Heavy industries are at a critical crossroads, where environmental responsibility meets economic viability. The global push toward net-zero emissions is reshaping manufacturing, steel production, cement making, and chemical processing industries with unprecedented urgency.

As climate change accelerates and regulatory frameworks tighten worldwide, industrial giants can no longer afford to postpone their decarbonization strategies. The transformation of these carbon-intensive sectors represents both a monumental challenge and an extraordinary opportunity for innovation, job creation, and sustainable economic growth that benefits communities and ecosystems alike.

🏭 Understanding the Decarbonization Imperative in Heavy Industries

Heavy industries account for approximately 30% of global carbon dioxide emissions, making them essential players in the fight against climate change. Steel, cement, chemicals, and aluminum production have traditionally relied on fossil fuel-intensive processes that seemed unchangeable for decades. However, technological breakthroughs and economic incentives are now making green alternatives not just possible but increasingly profitable.

The urgency stems from multiple converging factors. International agreements like the Paris Climate Accord have set ambitious targets, while consumers and investors increasingly demand environmental accountability. Meanwhile, carbon pricing mechanisms and stricter environmental regulations are making business-as-usual approaches financially unsustainable. Forward-thinking companies recognize that early adoption of decarbonization strategies provides competitive advantages through improved efficiency, brand reputation, and access to green financing.

Revolutionary Technologies Reshaping Industrial Energy Systems

The technological landscape for industrial decarbonization has evolved dramatically in recent years. Innovations once considered experimental are now reaching commercial viability, offering practical pathways for emissions reduction across various sectors.

Green Hydrogen: The Game-Changing Energy Carrier ⚡

Green hydrogen produced through electrolysis powered by renewable energy represents perhaps the most promising breakthrough for heavy industries. Unlike conventional hydrogen production that relies on natural gas reforming, green hydrogen generates zero emissions during production. Steel manufacturers are pioneering direct reduced iron processes using hydrogen instead of coal, potentially eliminating up to 95% of emissions from steelmaking.

Major industrial players in Europe and Asia have already launched pilot projects demonstrating the technical feasibility of hydrogen-based production. The challenge now shifts toward scaling production, reducing costs through economies of scale, and developing the necessary infrastructure for hydrogen storage and distribution. Government subsidies and private investment are accelerating this transition, with projections suggesting green hydrogen could become cost-competitive with fossil fuels within the next decade.

Carbon Capture, Utilization, and Storage (CCUS)

For industries where process emissions are unavoidable, carbon capture technologies offer a critical solution. Modern CCUS systems can capture up to 90% of CO2 emissions from industrial facilities, preventing them from entering the atmosphere. The captured carbon can either be permanently stored in geological formations or utilized as feedstock for producing valuable chemicals, building materials, or synthetic fuels.

Recent technological improvements have significantly reduced the energy penalty associated with carbon capture, making it more economically attractive. Cement producers, which face substantial process emissions from limestone calcination, are particularly enthusiastic about CCUS as an essential component of their decarbonization strategies. Innovative startups are developing novel capture materials and processes that promise even greater efficiency gains in the coming years.

🔄 Circular Economy Principles Driving Industrial Transformation

Beyond energy transitions, heavy industries are embracing circular economy principles that fundamentally reimagine production systems. This approach moves away from linear “take-make-dispose” models toward closed-loop systems that minimize waste and maximize resource efficiency.

Steel recycling through electric arc furnaces exemplifies this transformation. Using recycled scrap requires only about 25% of the energy needed for primary steel production, dramatically reducing emissions. Similarly, cement manufacturers are incorporating alternative materials like fly ash, slag, and calcined clay to reduce clinker content, which is the most carbon-intensive component of cement.

The chemical industry is developing bio-based feedstocks to replace petroleum-derived materials, creating products from agricultural waste, algae, and other renewable sources. These innovations not only reduce carbon footprints but also decrease dependence on finite fossil resources, enhancing long-term sustainability and supply chain resilience.

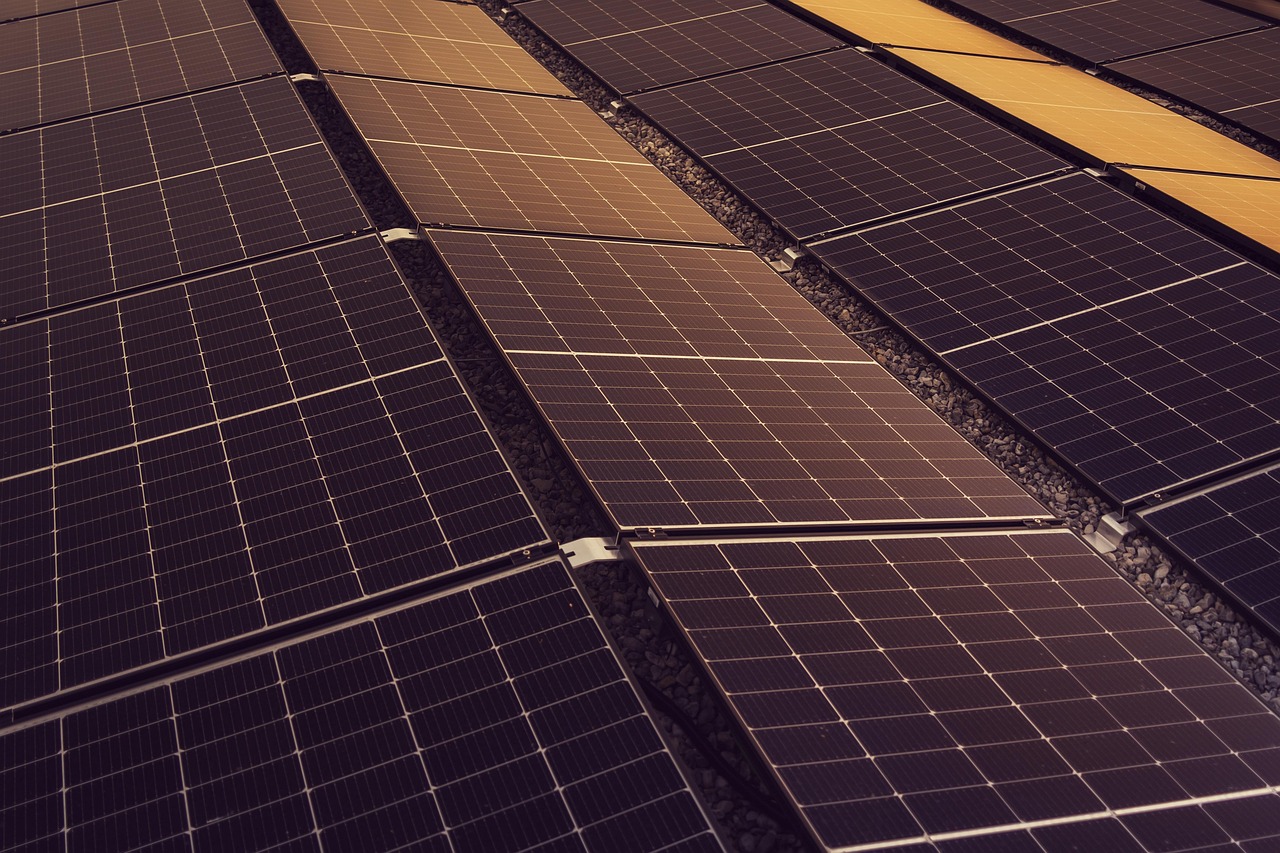

Electrification: Powering Industries with Clean Energy

Industrial electrification powered by renewable sources represents a straightforward yet powerful decarbonization strategy. Heat pumps can replace gas boilers for low-temperature industrial processes, while electric furnaces are transforming high-temperature applications in sectors like glass manufacturing and metal processing.

The key enabler is the rapid expansion of renewable electricity generation capacity. Solar and wind power costs have plummeted by more than 80% over the past decade, making clean electricity increasingly abundant and affordable. Industries are securing long-term renewable energy supplies through power purchase agreements, on-site generation, and participation in virtual power networks.

Battery storage systems and smart grid technologies are addressing the intermittency challenges associated with renewable energy, enabling industries to maintain consistent operations while maximizing clean energy utilization. This infrastructure development creates synergies between industrial decarbonization and broader energy system transformation.

💡 Digital Technologies Optimizing Industrial Sustainability

Artificial intelligence, machine learning, and Internet of Things sensors are revolutionizing how industries monitor, manage, and optimize their environmental performance. These digital tools enable unprecedented precision in resource management and emissions reduction.

Predictive Analytics and Process Optimization

Advanced algorithms analyze vast datasets from industrial operations to identify efficiency opportunities invisible to human operators. Machine learning models can optimize furnace temperatures, chemical reaction conditions, and material flows to minimize energy consumption while maintaining product quality. Some facilities report energy reductions of 10-20% through AI-driven optimization alone.

Predictive maintenance systems use sensor data to anticipate equipment failures before they occur, preventing costly downtime and reducing waste from production disruptions. These systems also ensure that equipment operates at peak efficiency, minimizing unnecessary energy consumption and emissions.

Digital Twins for Sustainable Design

Digital twin technology creates virtual replicas of industrial facilities, enabling companies to test decarbonization strategies without disrupting actual operations. Engineers can simulate the impact of equipment upgrades, process modifications, or fuel switching scenarios to identify the most effective interventions before committing capital investments.

This approach significantly reduces the risk associated with major industrial transformations, accelerating decision-making and implementation. Companies can also use digital twins for training personnel on new low-carbon technologies before they’re installed, smoothing transitions and reducing operational disruptions.

Policy Frameworks Accelerating Industrial Decarbonization 📋

Government policies play a crucial role in creating the economic conditions necessary for large-scale industrial transformation. Carbon pricing mechanisms, whether through carbon taxes or cap-and-trade systems, internalize the environmental costs of emissions and create financial incentives for reduction.

Regulatory standards are becoming increasingly stringent, with many jurisdictions implementing emissions performance standards that effectively mandate technology adoption. Border carbon adjustments are emerging as tools to prevent carbon leakage and ensure that imported goods meet comparable environmental standards.

Equally important are supportive policies including research and development funding, deployment subsidies for early-stage technologies, and public procurement preferences for low-carbon industrial products. Infrastructure investments in renewable energy, hydrogen networks, and CO2 transport systems create the enabling conditions for industrial transformation at scale.

🌍 Regional Leaders and Best Practice Examples

Different regions are pioneering distinct approaches to industrial decarbonization, offering valuable lessons for global implementation.

European Union’s Comprehensive Strategy

The EU has established ambitious targets through its Green Deal, aiming for climate neutrality by 2050. The region combines stringent emissions trading systems with substantial funding for green technology development and deployment. Industrial clusters focused on hydrogen production and CCUS infrastructure are emerging across Germany, the Netherlands, and Scandinavia.

The EU’s Carbon Border Adjustment Mechanism represents a groundbreaking policy innovation designed to protect domestic industries while encouraging global emissions reductions. This approach may serve as a template for other regions seeking to balance environmental ambition with industrial competitiveness.

Asia’s Manufacturing Transformation

China, Japan, and South Korea have announced substantial investments in industrial decarbonization as part of their net-zero commitments. China’s focus on electric vehicles and battery production is creating massive demand for low-carbon steel and chemicals, driving innovation throughout supply chains. Japan is pioneering hydrogen technologies with government-industry partnerships focused on commercialization and cost reduction.

South Korea’s Green New Deal includes significant funding for retrofitting existing industrial facilities with clean technologies, demonstrating that transformation doesn’t always require building from scratch. These Asian initiatives are particularly significant given the region’s dominant role in global manufacturing.

Financing the Industrial Transition 💰

The scale of investment required for industrial decarbonization is substantial, estimated at trillions of dollars globally over the coming decades. However, innovative financing mechanisms are emerging to mobilize the necessary capital.

Green bonds specifically designated for decarbonization projects have seen explosive growth, providing industries with access to capital from environmentally conscious investors. Sustainability-linked loans offer interest rate reductions tied to achieving emissions reduction targets, aligning financial incentives with environmental performance.

Public-private partnerships are proving essential for sharing the risks associated with deploying novel technologies at commercial scale. Development banks and international financial institutions are creating dedicated funds for industrial transformation in developing economies, ensuring that decarbonization doesn’t exacerbate global inequalities.

The growing recognition that climate risks represent financial risks is transforming corporate decision-making. Investors increasingly view decarbonization investments not as costs but as necessary measures to protect long-term asset values and ensure business continuity in a carbon-constrained future.

Workforce Transformation and Social Considerations

Industrial decarbonization will fundamentally reshape employment patterns, creating both challenges and opportunities for workers and communities. Proactive workforce development strategies are essential to ensure that transitions are socially just and economically inclusive.

Many green technologies require new skill sets, creating demand for training programs and educational initiatives. Fortunately, many skills from traditional industries transfer readily to low-carbon alternatives, enabling workforce transitions rather than wholesale displacement. Welders, electricians, and process engineers will remain essential, though their specific applications will evolve.

Union partnerships and community engagement are proving critical for building social support for industrial transformation. Successful transitions involve workers and communities in planning processes, ensuring that concerns are addressed and benefits are shared equitably. Regions that have prospered through extractive or carbon-intensive industries require particular attention, with policies designed to diversify economies and create new opportunities.

🚀 Emerging Technologies on the Horizon

Beyond technologies already reaching commercial deployment, a pipeline of innovative solutions promises to accelerate decarbonization in coming years. Molten oxide electrolysis could revolutionize steelmaking by eliminating the need for carbon reduction entirely, producing pure iron directly from ore using electricity.

Advanced nuclear reactors designed specifically for industrial heat applications could provide emissions-free high-temperature energy for processes currently dependent on fossil fuels. Small modular reactors offer potential for deployment at individual facilities, providing baseload power independent of grid constraints.

Biotechnology approaches are yielding enzymes and microorganisms capable of producing chemicals and materials through biological processes at ambient temperatures and pressures, dramatically reducing energy requirements compared to conventional thermochemical methods. These biological production systems could transform the chemical industry within decades.

Measuring Progress and Ensuring Accountability

Robust measurement and verification systems are essential for tracking decarbonization progress and ensuring that claimed reductions represent genuine emissions decreases rather than accounting manipulations. Standardized methodologies for calculating lifecycle emissions, including scope 3 supply chain emissions, are becoming increasingly sophisticated and widely adopted.

Blockchain and distributed ledger technologies offer promising solutions for creating transparent, tamper-proof records of emissions and renewable energy consumption. These systems can track the carbon intensity of specific products through complex supply chains, enabling more accurate environmental claims and empowering consumers to make informed choices.

Third-party verification and certification schemes provide independent assurance of environmental performance, building trust with stakeholders and differentiating leaders from laggards. As sustainability reporting becomes mandatory in more jurisdictions, these verification systems will become increasingly important for corporate compliance and reputation management.

🌱 The Path Forward: Integration and Acceleration

Industrial decarbonization is no longer a question of technical feasibility but rather of implementation pace and coordination. The technologies, policies, and financing mechanisms necessary for transformation largely exist today, though continued innovation will expand options and reduce costs.

Success requires coordinated action across multiple dimensions: technology deployment, policy development, infrastructure investment, workforce training, and international cooperation. No single solution will suffice; rather, portfolios of complementary strategies tailored to specific industrial contexts and regional circumstances offer the most promising pathway.

The business case for decarbonization strengthens daily as clean technologies mature, carbon prices rise, and stakeholder expectations intensify. Early movers are establishing competitive advantages that will compound over time, while delay creates escalating risks of stranded assets, market share loss, and regulatory penalties.

The transformation of heavy industries represents one of the defining challenges and opportunities of our era. By embracing innovative decarbonization pathways, these sectors can secure their long-term viability while contributing meaningfully to global climate goals. The greener future is not a distant aspiration but an emerging reality, powered by human ingenuity, technological innovation, and collective determination to build a sustainable industrial system that serves both people and planet.

Toni Santos is a social innovation researcher and writer exploring how technology, entrepreneurship, and community action can build a more equitable future. Through his work, Toni highlights initiatives that merge ethics, sustainability, and innovation to create measurable impact. Fascinated by the relationship between human creativity and collective progress, he studies how people and ideas come together to solve global challenges through collaboration and design thinking. Blending sociology, technology, and sustainable development, Toni writes about the transformation of communities through innovation with purpose. His work is a tribute to: The power of community-driven innovation The vision of entrepreneurs creating social good The harmony between progress, ethics, and human connection Whether you are passionate about social entrepreneurship, sustainable technology, or community impact, Toni invites you to explore how innovation can change lives — one idea, one action, one community at a time.